Advantages of WÖHWA Batching Combinations

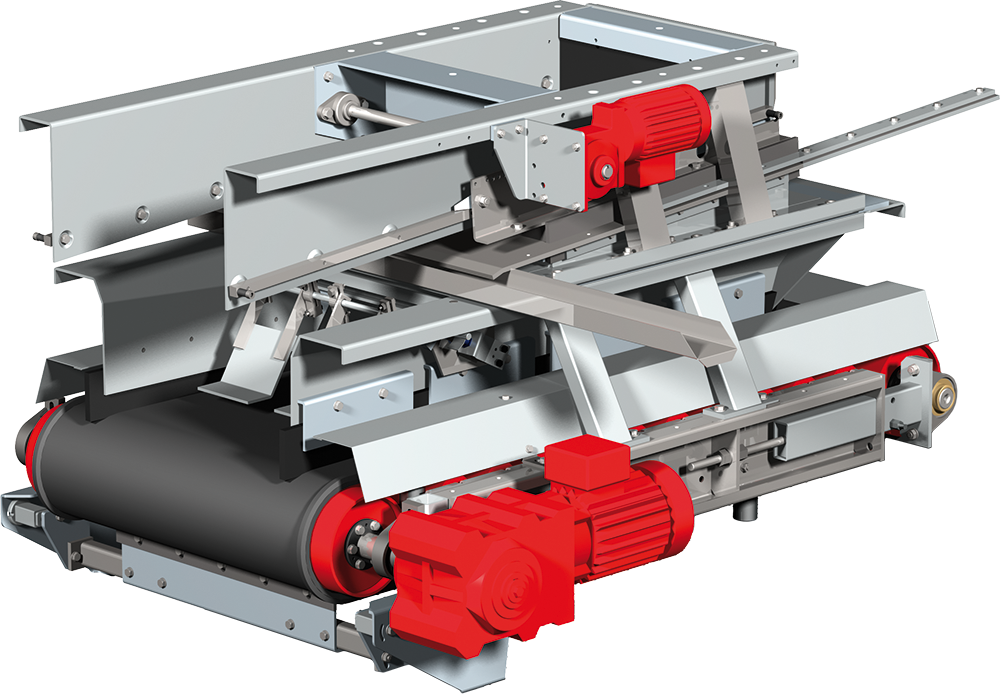

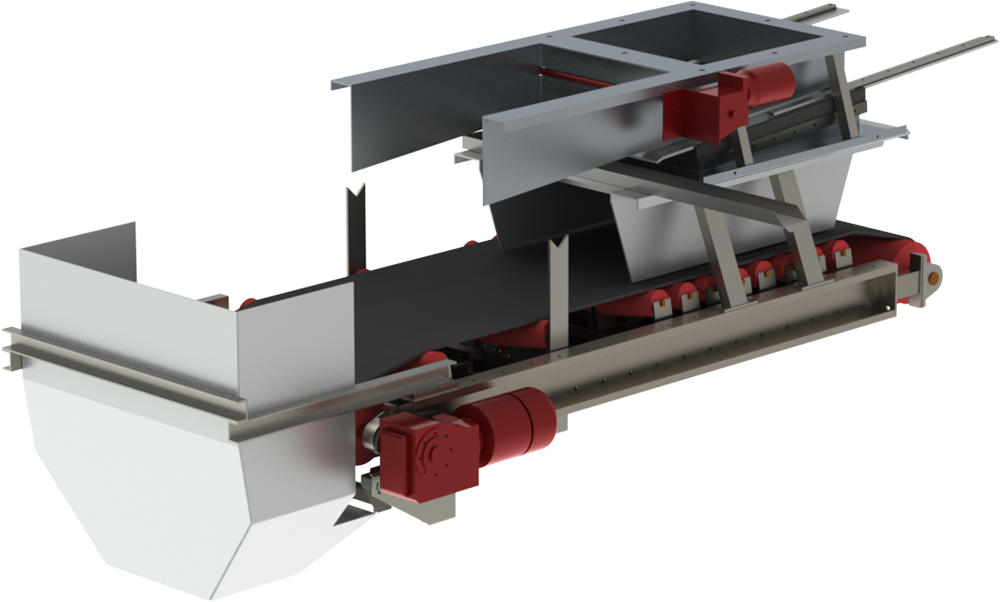

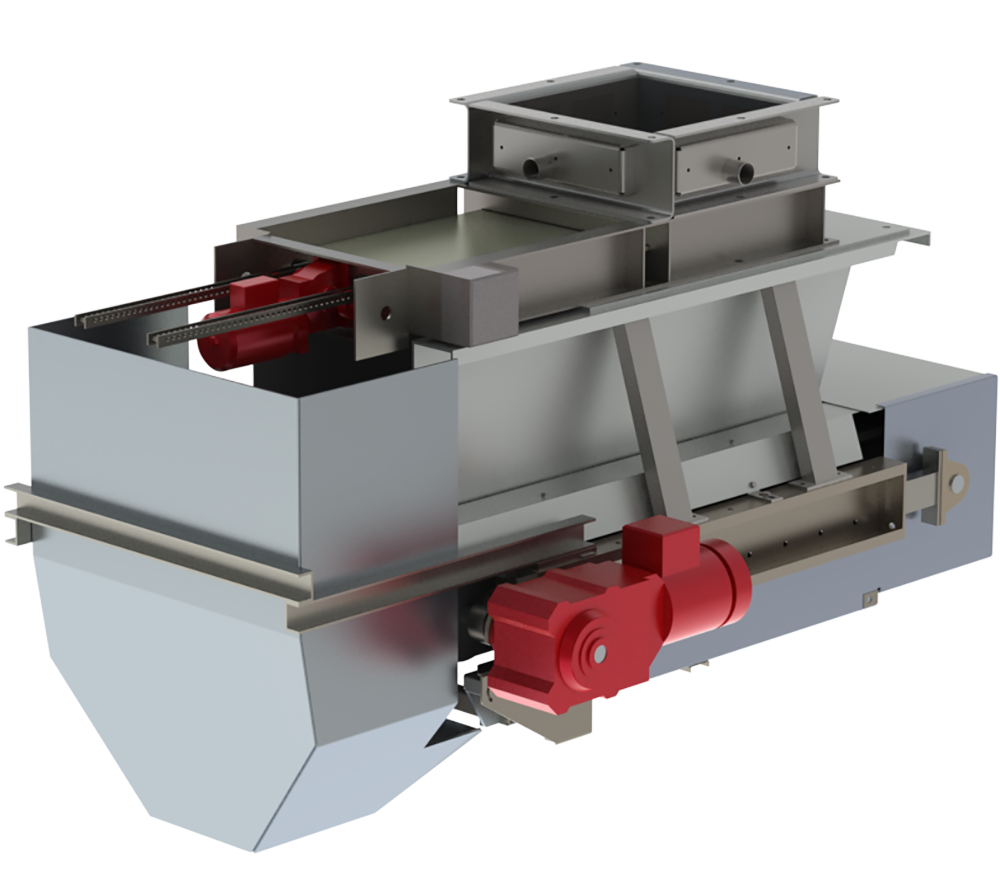

- Easily replaceable motors

- Robust design

- Hardox lining available

- Adjustable Vulkolan sealings

- Fully galvanized

- Self-adjusting outer cleaner

- Four-layer conveyor belt type EP 400-3

- Cambered end pulley

- Adjustment range ca. 1:20

- 3 kW motor (different motors available)

- Robust straight bevel gear pair

The use of WÖHWA belt feeders is a safe method for the reclaim of poorly flowing bulk materials (e.g. sand) or for small blending or loadout quantities. Desired percentages in blends can be achieved by using frequency converters for variable belt speeds. Standard reclaim/feed quantities of 3 to 1000 t/h can be achieved dependant upon belt width, height of material carpet, particle sizes and flow characteristics. Corrugated side wall belts or trapezoidal flat belts are used for an optimized material flow.

WÖHWA belt feeders have a modular design. Any belt feeder size and any optional part can be supplied at short notice. All parts are hot-dip galvanized. Gear drive and bearings are maintenance-free.

- robust design

- maintenance-free

- all bearings lubricated for life

- galvanized

The carefully selected drive mechanism components provide a powerful and reliable drive force.

- robust straight bevel gear pair

- slip-on gear drive

- wide adjustment range when used with frequency converter (approx. 1:20)

drawings

|

Belt Feeder 10.06 (650) Sliding Gate 01.1.55 height of product layer 200 mm |

zipped DWG PDF |

|

Belt Feeder 10.06 (650) Sliding Gate 01.1.55 height of product layer 300 mm |

zipped DWG PDF |

|

Belt Feeder 10.06 (650) Sliding Gate 01.1.55 height of product layer 400 mm |

zipped DWG PDF |

|

Belt Feeder 10.08 (800) Sliding Gate 01.1.66 height of product layer 200 mm |

zipped DWG PDF |

|

Belt Feeder 10.08 (800) Sliding Gate 01.1.66 height of product layer 300 mm |

zipped DWG PDF |

|

Belt Feeder 10.08 (800) Sliding Gate 01.1.66 height of product layer 400 mm |

zipped DWG PDF |

|

Belt Feeder 10.10 (1000) Sliding Gate 01.1.66 height of product layer 200 mm |

zipped DWG PDF |

|

Belt Feeder 10.10 (1000) Sliding Gate 01.1.66 height of product layer 300 mm |

zipped DWG PDF |

|

Belt Feeder 10.10 (1000) Sliding Gate 01.1.66 height of product layer 400 mm |

zipped DWG PDF |

|

Belt Feeder 10.12 (1200) Sliding Gate 01.1.88 height of product layer 400 mm |

zipped DWG PDF |

Downloads

| Deutsch | English | Français | |

|---|---|---|---|

| Operation and Maintenance Instructions | |||

| Connection of Belt Feeders with Frequency Inverter and MPM100 Module | — | ||

| Spare Parts List | |||

|

Operating and Maintenance Instruction Helical-Bevel Gearboxes |

|||

| Data Sheet Limit Switch VEES Ö 2L | |||

| Data Sheet Limit Switch VEES Ö 3L | |||

| Data Sheet Limit Switch VEES S 2L | |||

| Data Sheet Limit Switch VEES S 3L |