Advantages of WÖHWA Weigh Belt Feeders

- Extremely robust design

- Hot-dip galvanized

- Modular design

- Manual or electric shut-off gate for repair purposes

- Automatic zero-setting with electrically driven shut-off gate

- Automatic belt-tensioning device

- High batching and weighing accuracy

- Pre-adjusted in factory

- Simple and fast re-adjustment with test weight (supplied by WÖHWA)

- Legal-for-trade (reclaim weigh feeders)

Quality, Continuity, Variability

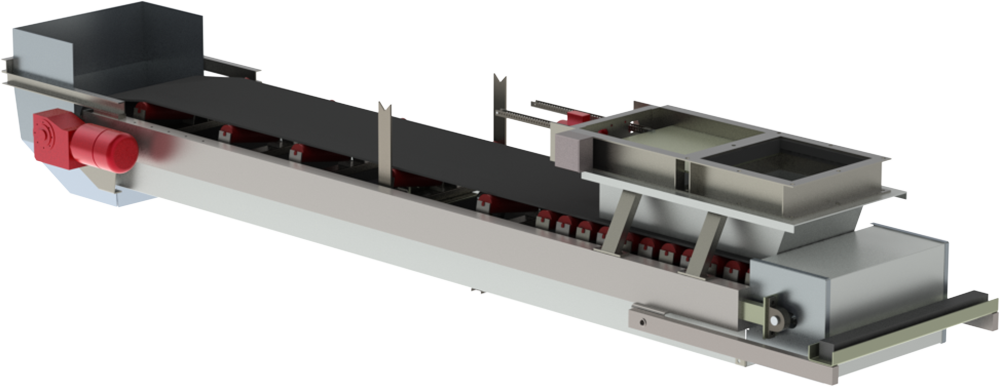

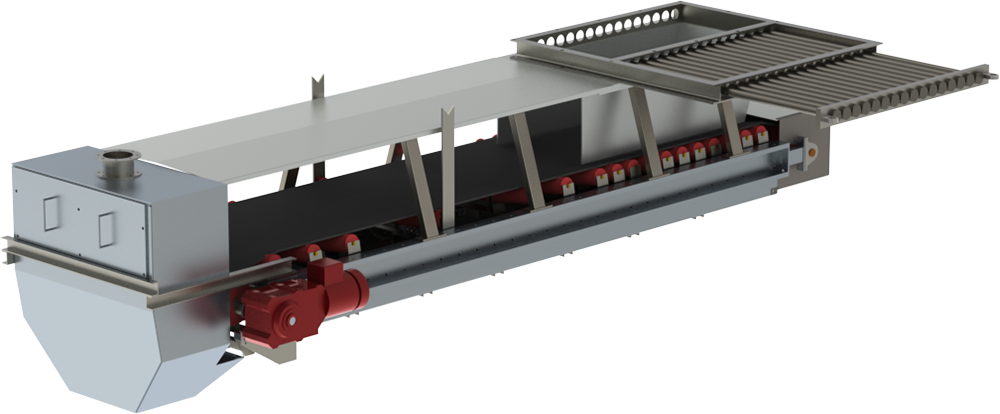

More than 50 years ago, WÖHWA developed the first weigh belt feeders for products with varying changes in flow characteristics and bulk density. All components and software for the modular designed weighing system are produced in-house at our factory. The modular design of the WÖHWA blending and reclaim weigh belt feeders allows an individual adaptation to on-site conditions while using standard components.

Each blending device can be equipped with either a manual WÖHWA shut-off/sealed gate or an electric slide gate. An electric slide gate allows automatic zero-setting of the belt scale.

The robust blending/reclaim weigh belt feeders can be supplied with belt widths from 400 mm (16 inches) to 1,400 mm (56 inches) to meet all application-specific requirements in respect of flow rate, product or flow characteristics. All standard components are cut on our own laser cutting machine and then hot-dip galvanized.

The weigh belt feeders can be supplied with troughed or flat belts. The well-designed construction protects the scale from any detrimental influences disturbing the high-accuracy weighing.

Each weigh belt feeder can be adapted in length and width to meet any customers' specific requirements. Prior to commencement of manufacturing, plans in PDF or DWG formats will be submitted to the customer for final approval. Connecting flange and chute can be individually adapted to any customer application. The weigh belt feeder is equipped with a slip-on gear drive. The motor power rating is optimally selected for any specified blending/reclaim rate (special motor versions also available).

Numerous options are available, such as dust covers, wear-resisting lining, water gutters, emergency-pull cords, sheet cover for reverse pulley, frequency converters, etc. All sensors are non-contacting. WÖHWA blending/reclaim weigh belt feeders can be easily combined with other WÖHWA components.

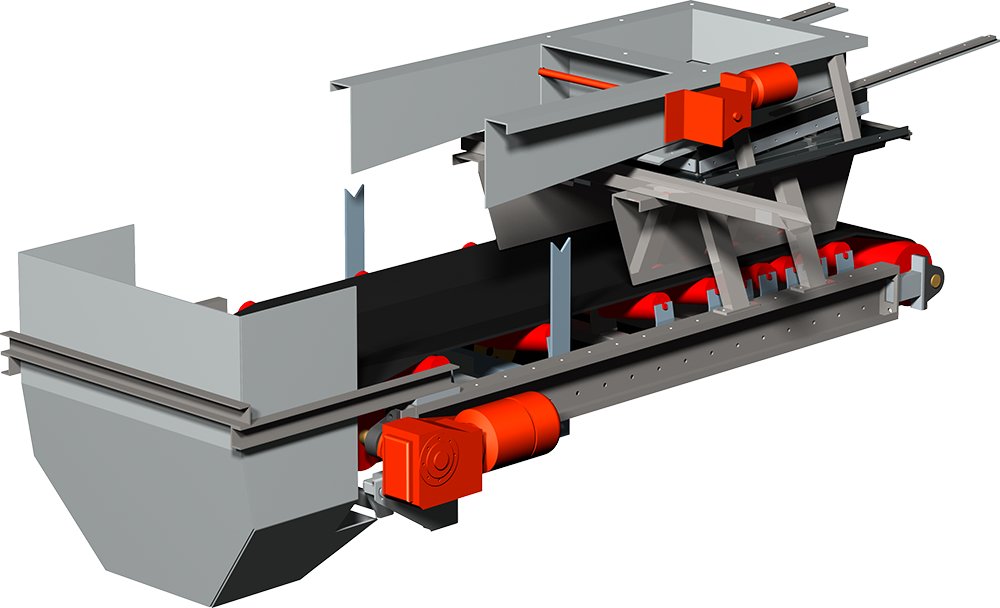

Set-Up of the WÖHWA Blending/Reclaim Weigh Belt Feeder

Slide Gate

Depending upon the application and product, the manual emergency shut-off gates, types 09 and 99, the pin gate, type 89, or the double-flange sealed gate, type 02, may be used as shut-off gates. The WÖHWA sealed gates, types 03 and 08.1 as well as the slide gates, type 01.1, can be supplied either with a motor or with only a hand-wheel. A combination of the various blending/reclaim feeders with the above listed gate types with opening widths ranging from 200 x 200 mm (8 x 8 inches) to 1,000 x 1,000 mm (40 x 40 inches) meets most flow rate requirements.

Connection Frame

The robust connection frame between slide gate and belt feeder prevents dust and dirt entering the slide mechanics. All slide gate components are freely accessible and can be changed without having to empty the stockpile or silo.

Feed Chute

The feed chute is mounted between connection frame and belt feeder and allows the forming of a material bed on the belt. The feed chute can be adapted to any customer application.

Blending/Reclaim Belt Feeder

Available standard versions:

- Belt widths ranging from 400 – 1,400 mm (16 to 55 inches)

- Material bed depth adjustable to max. 400 mm (16 inches)

- Belt feeder lengths ranging from 2 - 12 m ( 7 to 39 feet)

- Flow rates up to 2,500 t/h (special sizes upon request)

Chute

Lined with 10 mm (0.39 inches) polyurethane reducing wear and noise.

Automatic Belt Tensioning Device

A constant belt tension increases the weighing accuracy.

Belt Cleaner

Maintenance-free, self-adjusting outer belt cleaner with rubber spring element for easy belt cleaning. The V-shaped inner belt cleaner prevents belt damage from material intruding between belt and reverse pulley.

Belt Scale

Each belt scale is supplied with a robust digital tachometer (wheel) for measuring the belt speed. Sensor and bearing are hermetically sealed to prevent contamination from dirt.

Standard Functions

- Zero Setting

- Erase Weight

- Date/Time

- Print Log for consecutive number, date, time and weight (only with GCU 64)

- Pre-selection of total weight quantities

- Power Flow / Slow Flow Shut-Off

- Correction Factor

- Buffered Totalizer

Re-Adjustment

All scales are pre-adjusted at factory and can easily be re-adjusted on site with the supplied test weight.

Technical Features

- Modular

- Bolted

- Completely hot-dip galvanized

- Motor and bearings maintenance-free

- Adaptable flanges

- Chute (optional)

- Outer and inner belt cleaner

- Dust cover (optional)

- Lagged drive pulley (optional)

- Interfaces to dust extraction system (optional)

- High-resolution belt scale

- Robust measuring wheel (hermetically sealed)

- WÖHWA Weighing Terminal GCU 50 / GCU 64

- Serial interface RS-422 (optional)

- Analog interface 4-20 mA oder 0-10 V (optional)

- Integrated PID controller

- Operator Menu English/German/French (other languages optional)

- Custom-tailored software

- Connection of the belt scales directly via RS-422/485 or, optionally, via PROFIBUS to PC and PLC of WÖHWA Control System for Processing Plants, and WÖHWA Blending and Loadout System