Advantages of WÖHWA Sliding Gates

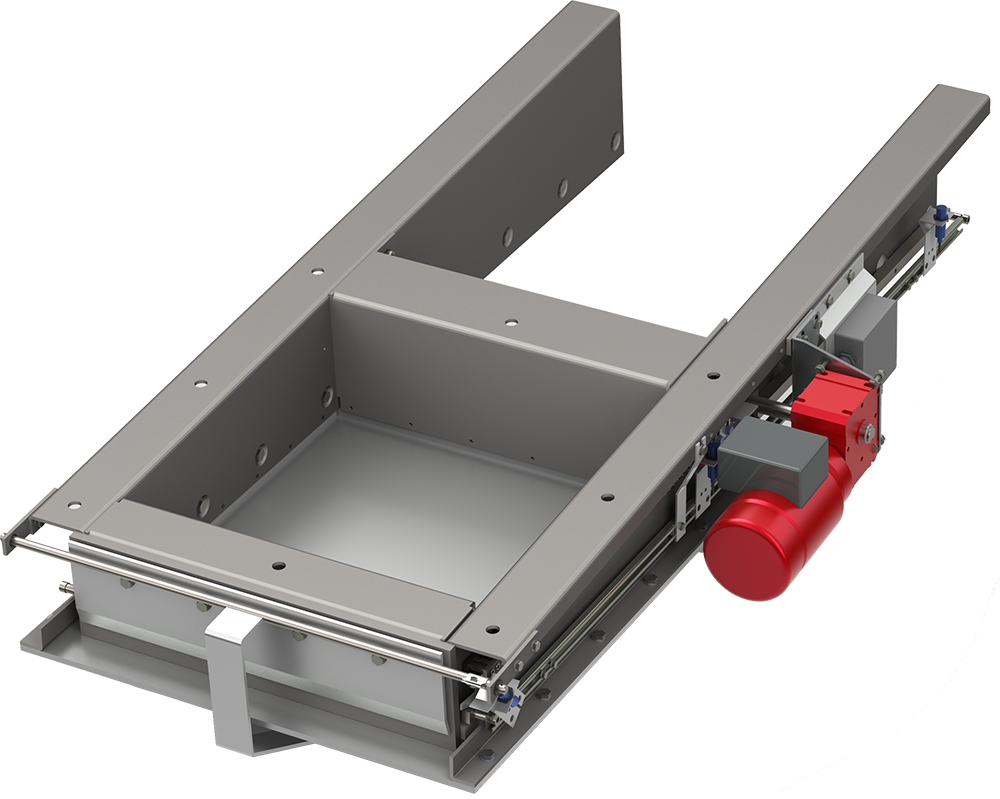

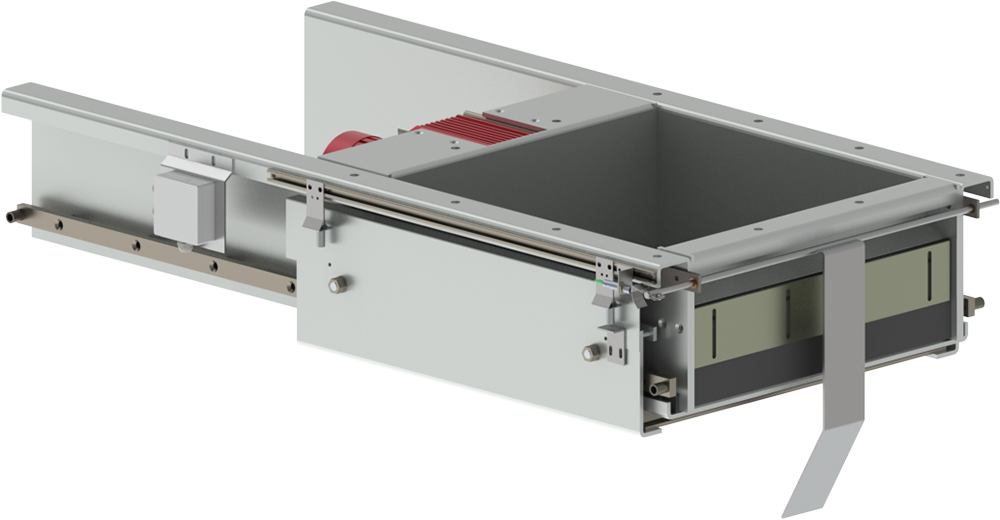

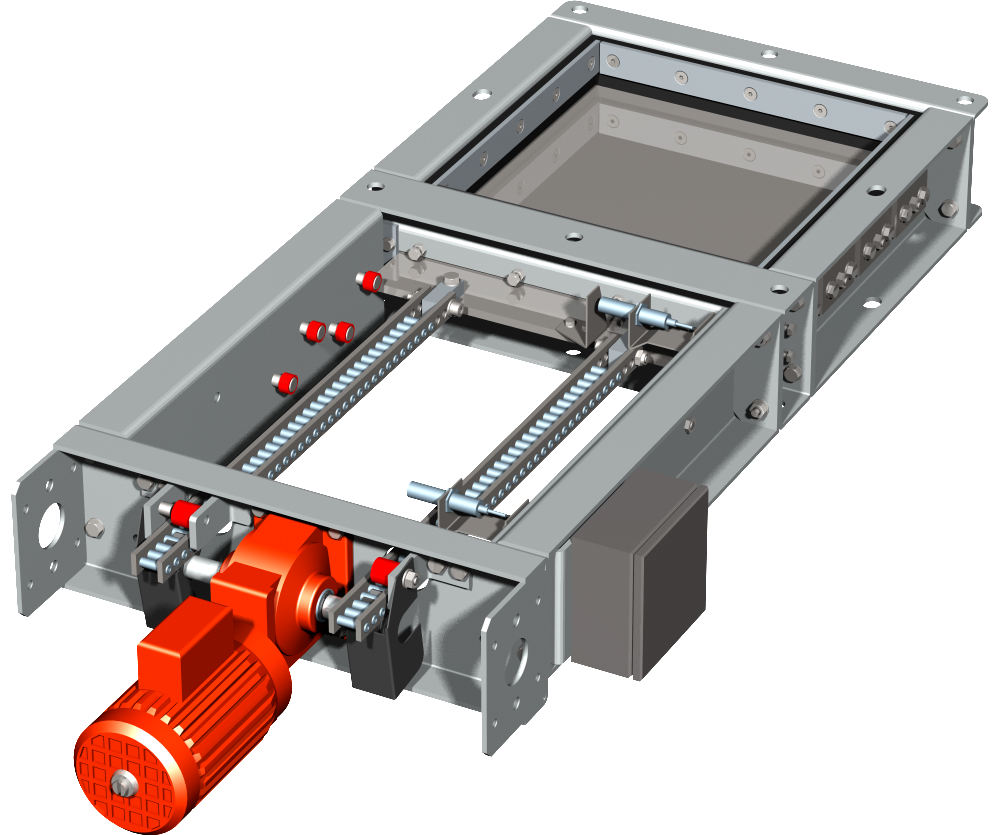

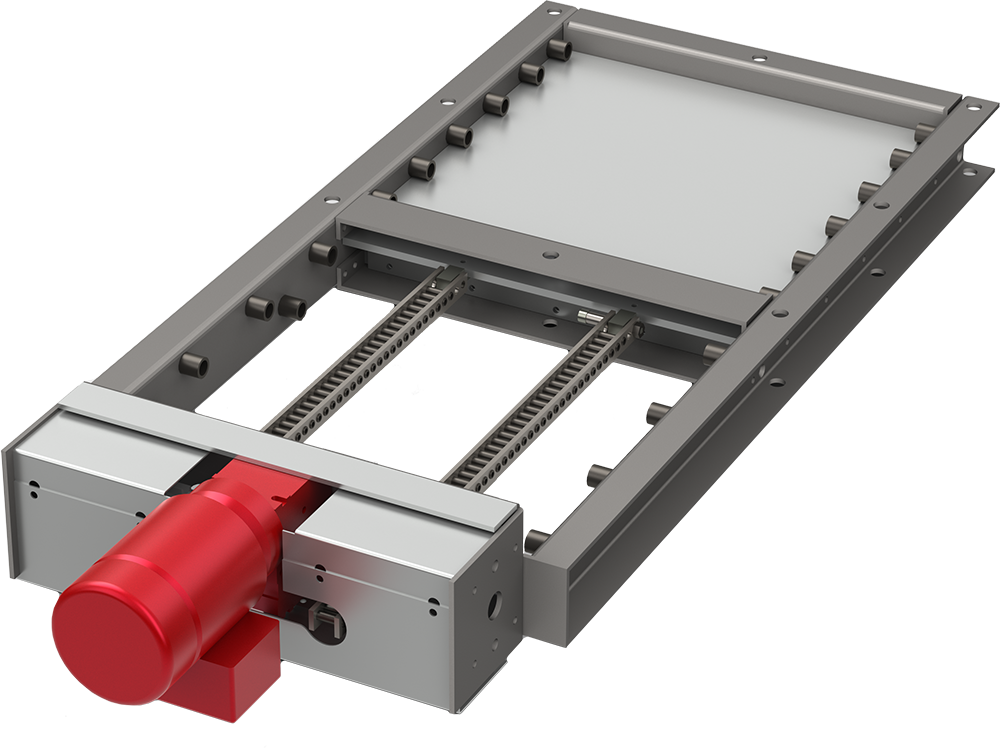

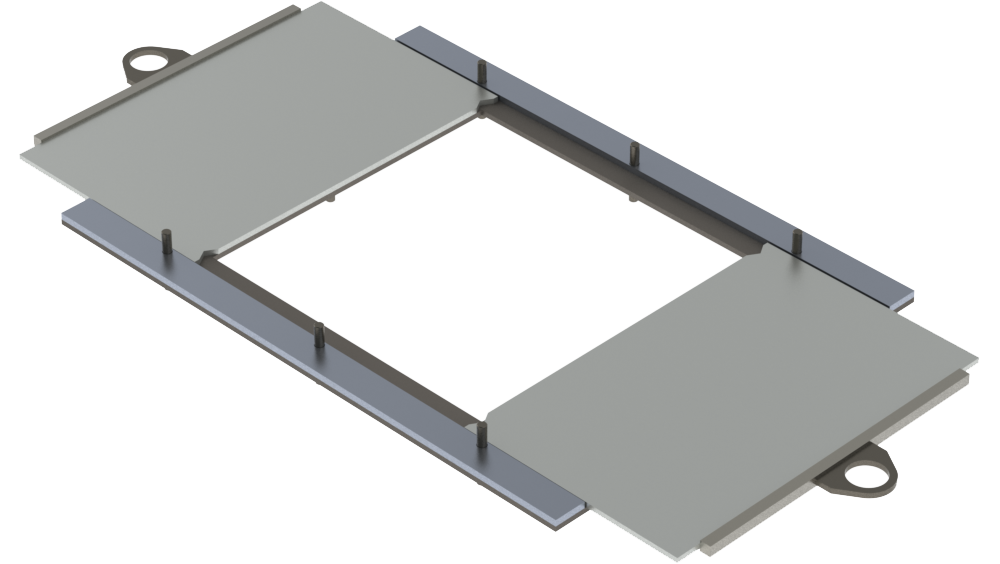

- Water drainage insert box for very wet bulk materials optionally available

- Motors easily replaceable

- Ruggedized

- Hardox wear-resistant lining optionally available

- Material Flow Controller

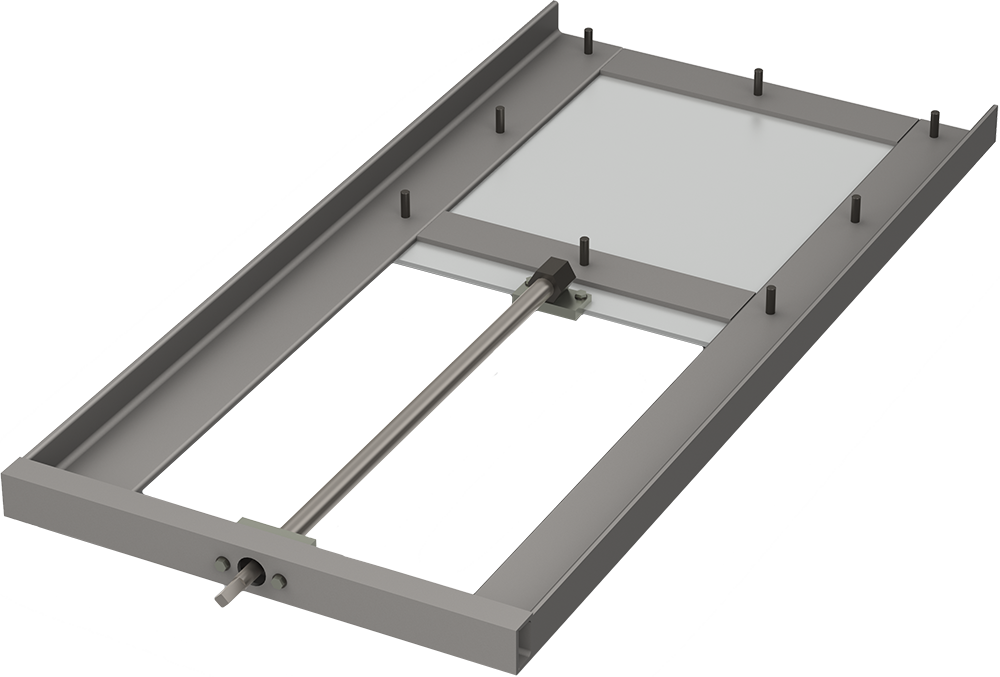

- Adjustable Vulkollan sealing strips

- Completely hot-dip galvanized

- Modular design

- Varying sizes

- Varying types for different applications

- Industrial-duty und Heavy Duty versions available

Quality and Continuity

More than 50 years ago, WÖHWA developed the method of blending with sliding gates. The cost-effective and energy saving blending method using the WÖHWA sliding gates replaced the industrial methods commonly used at that time. Currently, our customers use more than 40,000 WÖHWA sliding gates in combination with more than 2,000 WÖHWA blending systems all over the world. Many of these have been operational for decades. WÖHWA is in a position to supply spare parts for all types and versions. The WÖHWA sliding gates are continually upgraded and improved to suit additional customer-specific requirements.

Professionalism

WÖHWA sliding gates are designed in modules. Every sliding gate size and every optional component can be quickly supplied. All parts are hot-dip galvanized. Gear drive and bearings are maintenance-free.

Solutions for any Application

A wide product range including sliding gates, emergency shut-off gates, double-flange gates, and sealed hopper gates, with discharge openings of 200 x 200 mm to 800 x 800 mm, covers a numerous variety of applications.

The Principle

The bulk material quantity discharging from a silo per unit of time (discharge capacity in m³/h or t/h) remains constant with a given opening area, with consistent and pourable bulk material and with a bin/silo fill level of > 1.5 m.

With crushed stone and gravel, the specific discharge capacity is 40 to 60 t/h per dm² opening area. This hour-glass principle is the most economical production method for blending multiple aggregate gradings. WÖHWA recognized this more than 50 years ago when we introduced the sliding gates into the bulk materials industry.

For the reclaim of poorly flowing bulk materials (e.g. crushed sand or wet sand) or for small blending or loadout quantities, the use of WÖHWA belt feeders or batching combinations (sliding gate above a belt feeder) would be the better choice.

drawings type 01.1

| type opening size | with draining | without draining |

|---|---|---|

| type 01.1 200 mm x 200 mm | zipped DWG PDF | zipped DWG PDF |

| type 01.1 300 mm x 300 mm | zipped DWG PDF | zipped DWG PDF |

| type 01.1 400 mm x 400 mm | zipped DWG PDF | zipped DWG PDF |

| type 01.1 500 mm x 500 mm | zipped DWG PDF | zipped DWG PDF |

| type 01.1 600 mm x 600 mm | zipped DWG PDF | zipped DWG PDF |

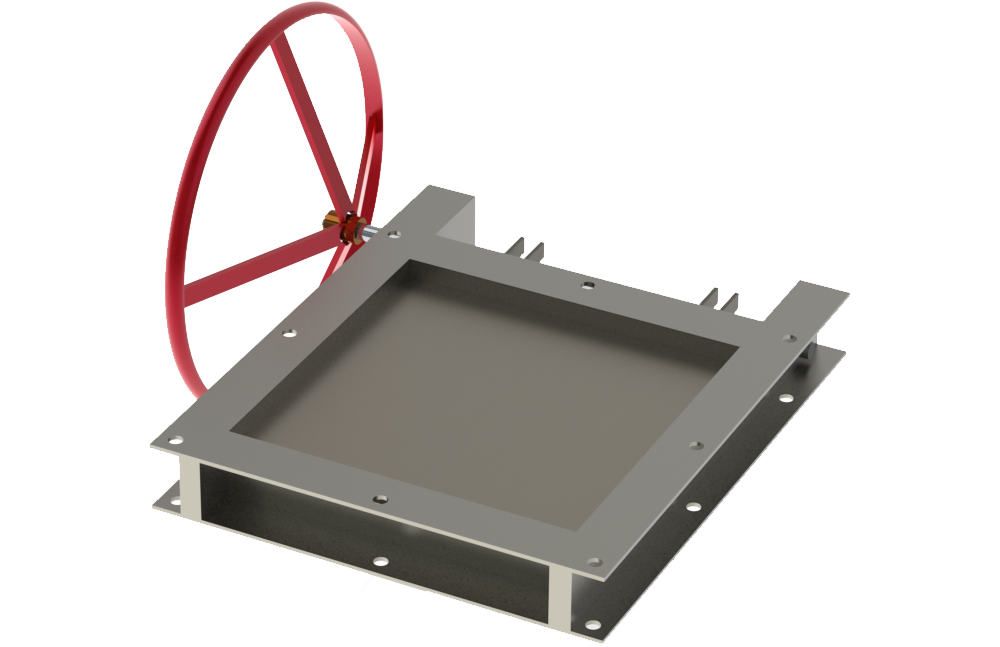

drawings type 02.

| type opening size | with handwheel | with handcrank |

|---|---|---|

| type 02. 200 mm x 200 mm | zipped DWG PDF | zipped DWG PDF |

| type 02. 300 mm x 300 mm | zipped DWG PDF | zipped DWG PDF |

| type 02. 400 mm x 400 mm | zipped DWG PDF | zipped DWG PDF |

| type 02. 500 mm x 500 mm | zipped DWG PDF | zipped DWG PDF |

drawings type 03.

| type opening size | with motor | with handwheel |

|---|---|---|

| type 03. 200 mm x 200 mm | zipped DWG PDF | zipped DWG PDF |

| type 03. 300 mm x 300 mm | zipped DWG PDF | zipped DWG PDF |

| type 03. 400 mm x 400 mm | zipped DWG PDF | zipped DWG PDF |

| type 03. 500 mm x 500 mm | zipped DWG PDF | zipped DWG PDF |

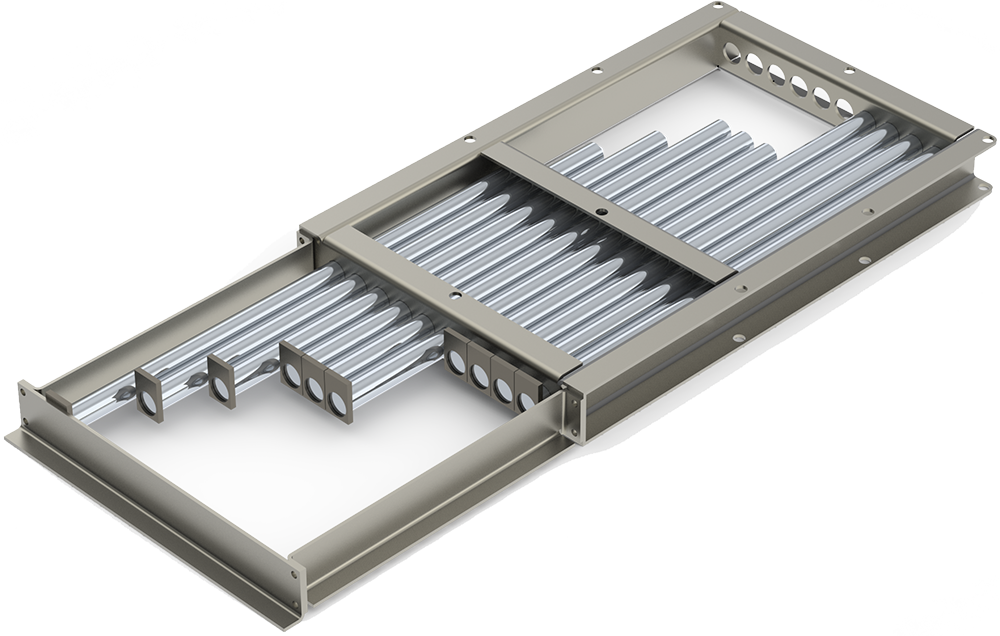

drawings type 08.1

| type opening size | with motor | with pneumatics |

|---|---|---|

| type 08.1 200 mm x 200 mm | zipped DWG PDF | zipped DWG PDF |

| type 08.1 300 mm x 300 mm | zipped DWG PDF | zipped DWG PDF |

| type 08.1 400 mm x 400 mm | zipped DWG PDF | zipped DWG PDF |

| type 08.1 500 mm x 500 mm | zipped DWG PDF | zipped DWG PDF |

| type 08.1 600 mm x 600 mm | zipped DWG PDF | zipped DWG PDF |

drawings type 89.

| type opening size | |

|---|---|

| type 89. 500 mm x 500 mm | zipped DWG PDF |

| type 89. 600 mm x 600 mm | zipped DWG PDF |

| type 89. 800 mm x 800 mm | zipped DWG PDF |

| type 89. 1.000 mm x 1.000 mm | zipped DWG PDF |

drawings type 09.

| type opening size | |

|---|---|

| type 09. 500 mm x 500 mm | zipped DWG PDF |

| type 09. 600 mm x 600 mm | zipped DWG PDF |

| type 09. 700 mm x 700 mm | zipped DWG PDF |

| type 09. 800 mm x 800 mm | zipped DWG PDF |

drawings type 99.

| type opening size | with ratchet | with handwheel |

|---|---|---|

| type 99. 500 mm x 500 mm | zipped DWG PDF | zipped DWG PDF |

| type 99. 600 mm x 600 mm | zipped DWG PDF | zipped DWG PDF |

| type 99. 700 mm x 700 mm | — | zipped DWG PDF |

| type 99. 800 mm x 800 mm | zipped DWG PDF | zipped DWG PDF |

| type 99. 1.000 mm x 1.000 mm | zipped DWG PDF | zipped DWG PDF |

Downloads

| Deutsch | English | Français | |

|---|---|---|---|

| Operation and Maintenance Instructions | |||

| Spare Parts List | |||

| Spare Parts List (old version) | |||

| Installation Instructions 0.55 kW | |||

| Installation Instructions 0.9 kW | |||

|

Operating and Maintenance Instruction Worm Gear Units, Typ SD / SI |

|||

| Data Sheet Limit Switch VEES Ö 2L | |||

| Data Sheet Limit Switch VEES Ö 3L | |||

| Data Sheet Limit Switch VEES S 2L | |||

| Data Sheet Limit Switch VEES S 3L |